PWM is leading the shift from reactive to preventive maintenance with smart monitoring, reducing downtime, cutting costs, and boosting reliability at gas stations.

Between October 1st and 3rd, 2025, the GIA Group held its annual meeting in Sarajevo. Partners from across Europe met to exchange ideas on current developments in gas station construction, service, and maintenance. Among the key presentations was “Preventive Maintenance”, introduced by Bastian Kaufmann, Sales Manager at PWM GmbH & Co. KG.

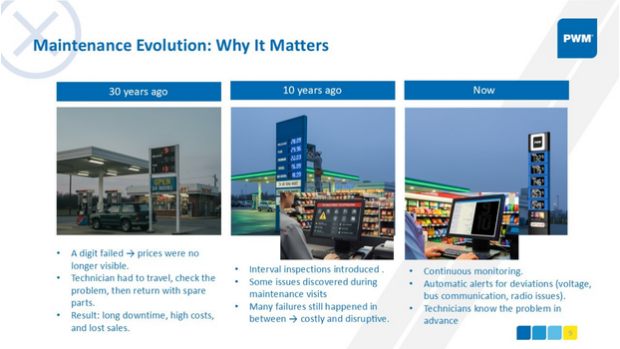

For a long time, maintenance across many industries followed a simple principle: repair only when something breaks. This reactive approach often resulted in costly downtimes and disrupted operations. The same applied to gas stations, a defective totem or price display not only interrupts functionality but also affects visibility and customer perception.

Today, the approach to maintenance is changing. Modern technology allows continuous monitoring of equipment, helping operators detect and resolve potential problems early, before they cause damage or loss of sales.

With its PWM Cloud Service, PWM supports this transition from reactive to preventive maintenance. Sensors installed in field equipment record key performance data such as temperature, voltage, and LED status among others. This information is analyzed in real time, providing clear alerts whenever irregularities occur. Service teams can act quickly and precisely, reducing downtime and avoiding unnecessary technician trips.

Preventive maintenance brings clear advantages:

- Less downtime and lower costs

- Extended product lifetime

- Reduced environmental impact

- Greater operational reliability

As a leading manufacturer of electronic price displays, PWM has always focused on innovation and long-term quality. Through the PWM Cloud Service, the company is helping station operators worldwide to take the next step toward smarter, more sustainable service management.

To learn more about PWM Cloud and its benefits, visit pwm.com.